Lithec USA news

Download COLOR RULES: A Roadmap for Successful Color Management and Ultimate Printing Efficiency

Developed by renowned industry experts, these guidelines have been established to ensure successful color management and ultimate printing efficiency. By following this proven and productive roadmap, you’ll optimize efficiency and maximize savings—from...

Color Rules: A Roadmap for Successful Color Management and Ultimate Printing Efficiency

PRINTING United Expo is the most dynamic and comprehensive printing event in the world. Bringing together the entire printing industry under one roof to experience over a million square feet of the latest equipment, solutions, and trends on the market!Introducing...

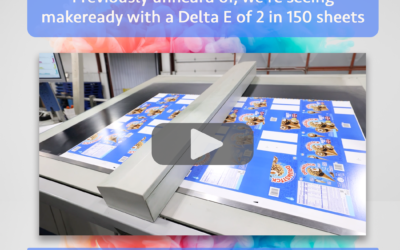

LithoFlash Controls Color and Shortens Makereadies at Range Printing

Range Printing is shortening makereadies between jobs with LithoFlash’s closed-loop management system.WOODSTOCK, GA — July 14, 2023 — Lithec, a global leader of inline color control and inspection systems for the graphic communications industry, announces the...

Previously unheard of, we’re seeing makeready with a Delta E of 2 in 150 sheets

Our best customers that have their press running correctly: they have their Ink Key presetting dialed in, they have their plate curves built correctly, their Ink Keys are zeroed out and working well. They are seeing makereadies with a delta e of 2 in 150 sheets. That...

LithoFlash Unit Yields Faster Make-Ready Times, 60% Less Paper Waste for Commercial Printer

Controlling and inspecting color inline helps Envision Printingto run faster and conserve press sheets WOODSTOCK, GA — May 24, 2023 — Lithec, a global leader of inline color control and inspection systems for the graphic communications industry, retrofitted a...

Lithec USA will be at Print UV 2023

Agenda for Print UV 2023 Announced A New Generation of Sheetfed UV Embellishments Print UV, the leading conference for UV printing, has announced the agenda for its upcoming conference, taking place from May 2-4, 2023 at the Encore at Wynn Las Vegas. This year's...

Can you retrofit your existing press with LithoFlash?

"Inline color control is not just for new presses! LithoFlash can be "bolted on" to your existing press in a simple field upgrade." Adding LithoFlash, the leading inline color control system, to your offset press can bring significant savings by reducing makeready and...

What would you do with 6 extra skids of paper?

"If you reduce that makeready from 300 sheets to 75 sheets that gives you an extra six skids per month to print with." Lithec saves money and paper waste for any packaging printer.

50th LithoFlash Unit to be Installed in North America this Spring

Installing 50th LithoFlash Unit in North America in 2023 Packaging Printer Malnove Inc adds 3 Inline color-control systems in their Omaha, NE plant to improve quality and conserve waste. WOODSTOCK, GA — February 21, 2023 — Lithec, a global leader of inline...

“We find we can push more work through at higher speeds, with less waste, and keeping color consistency throughout the press run.”

ANDREW GOETT – President

“The LithoFlash system allows us to maintain the G7 standards in our offset print operations,” “WE DON’T HAVE TO WORRY ABOUT MATCHING, WE KNOW WE WILL CONSISTENTLY HIT OUR COLOR TARGETS.”

JOHN YERGER – Pressman

“We identified the Lithec Litho-Flash as a way to take our current capital equipment, apply a relatively inexpensive product, and level the playing field with our competitors”

JEFF KU – Superior Litho

“Quality is absolutely critical in packaging,” says Bernie Lacy, President of Litho Press. “We decided to install the LithoFlash to not only help cut down on our makeready times, but also to ensure we have even greater color consistency throughout the entire run.

With this installed, we can now print more jobs per day, and they are higher quality, with better color across the board.”

BERNIE LACY – Vice President

“Since we have installed Litho-Flash our biggest cost savings has come with the amount of sheets we have saved. We’ve pretty much cut our make-readies in half”

We wanted to bring our older presses up to the newest technology. Litho-Flash allows us to take an older press and achieve some of those quality expectations they have on new presses.

JIM EAKIN – Superior Litho