Lithec USA news

How can I make my press more profitable?

In our current business climate, printers are evaluating how to get more life out of their existing capital equipment investment in their offset press. At the same time, the market demands that your press is as productive as possible. Check out the short video above...

Lithec LithoFlash Ran Successful at PRINTING United

LAS VEGAS, NV – November 3, 2022 | Lithec, a global leader of inline color control and inspection systems for the graphic communications industry, achieved success running live demonstrations featuring Lithec LithoFlash at PRINTING United on October 19-21, in Las...

Lithec LithoFlash running live at PRINTING United

WOODSTOCK, GA – September 21, 2022 | Lithec, a global leader of inline color control and inspection systems for the graphic communications industry, announces that it will be running live demonstrations featuring Lithec LithoFlash at PRINTING United on October 19-21,...

Primary Color Reduces Makeready Waste with LithoFlash

WOODSTOCK, GA – June 30, 2022 – Primary Color LLC, part of the Garden Marketing Group, is an innovating producer of plant tags and horticultural manufacturing products. Since 2014, this Dallas, TX based printer has continued to expand the tag and label printing to...

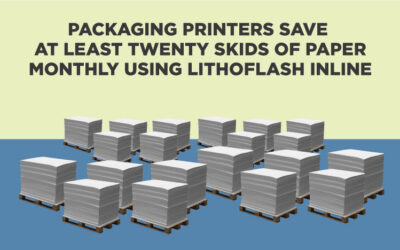

Packaging Printers who use LithoFlash save at least 20 skids of paper per month

We’re all feeling the supply chain pinch this year, which means an efficiently run print shop is more important than ever before. On average, users that have installed the LithoFlash Inline system save approximately 3,300 sheets of paper per day. This may not sound...

Commercial Printers who use LithoFlash save at least six skids of paper per month

We’re all feeling the supply chain pinch this year, which means an efficiently run print shop is more important than ever before. On average, users that have installed the LithoFlash Inline system save at least 1,800 sheets of paper per day. This may not sound like...

Atlantic Packaging streamlined with LithoFlash

TAKING COLOR CONTROL TO THE NEXT LEVEL WITH LITHOFLASH FROM LITHEC USA

Atlantic Packaging Saves Labor and Makeready with Lithec LithoFlash

WOODSTOCK, GA — Nov 4, 2021 — Celebrating 75 years in business, Atlantic Packaging specializes in the niche market of sustainable packaging. Atlantic Packaging has evolved from a small-town Pulitzer Prize winning newspaper into a uniquely positioned packaging resource...

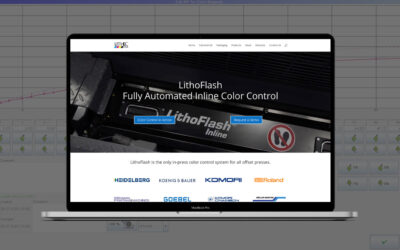

Welcome to the new Lithec.com

Don't stop the press! We've redesigned our website to give our valued customers the most useful resources for their businesses. From news stories to industry trends to client success stories, watch videos and listen to our new podcast about how both commercial and...

“We find we can push more work through at higher speeds, with less waste, and keeping color consistency throughout the press run.”

ANDREW GOETT – President

“The LithoFlash system allows us to maintain the G7 standards in our offset print operations,” “WE DON’T HAVE TO WORRY ABOUT MATCHING, WE KNOW WE WILL CONSISTENTLY HIT OUR COLOR TARGETS.”

JOHN YERGER – Pressman

“We identified the Lithec Litho-Flash as a way to take our current capital equipment, apply a relatively inexpensive product, and level the playing field with our competitors”

JEFF KU – Superior Litho

“Quality is absolutely critical in packaging,” says Bernie Lacy, President of Litho Press. “We decided to install the LithoFlash to not only help cut down on our makeready times, but also to ensure we have even greater color consistency throughout the entire run.

With this installed, we can now print more jobs per day, and they are higher quality, with better color across the board.”

BERNIE LACY – Vice President

“Since we have installed Litho-Flash our biggest cost savings has come with the amount of sheets we have saved. We’ve pretty much cut our make-readies in half”

We wanted to bring our older presses up to the newest technology. Litho-Flash allows us to take an older press and achieve some of those quality expectations they have on new presses.

JIM EAKIN – Superior Litho