Lithec USA news

Color Rules 11: RGB Camera versus Spectral Scanner Featuring Jack Frank

RGB vs Spectral Scanning: A Pressroom Perspective What’s the best way to maintain color consistency in print production—an RGB camera or a spectral scanner? In this quick but insightful video, Jack Frank from WestRock shares why they rely on the LithoFlash RGB camera,...

Lithec Announces Successful Integration of LithoFlash Inline at Great Little Box Company

WOODSTOCK, GA — April 24, 2025 — Lithec, a global leader of inline color control and inspection systems for the graphic communications industry, installed LithoFlash at Great Little Box Company’s British Columbia plant in October 2024. In just a few months since the...

Join Us for an Unmatched Experience at PRINT UV 2025!

Lithec is proud to exhibit at PRINT UV 2025, the industry's premier conference for UV printing professionals. This exciting event, set to take place at the luxurious Encore by Wynn Las Vegas, is your opportunity to engage with the brightest minds in UV and LED UV...

Pacific Southwest Container Adds LithoFlash In-LineColor Control in Northern California Plant

Closed-loop LithoFlash system on 64-inch sheetfed press is helping Pacific Southwest Container to increase precious uptime. WOODSTOCK, GA — January 27, 2025 — Lithec, a global leader of inline color control and inspection systems for the graphic communications...

Color Rules: How often does the camera read the color bar?

Phase 10 of the “Color Rules” covers the common question: How often does the camera read the color bar? The video goes in-depth into managing ink zones on the KBA press and breaks down the process step by step, explaining how ink settles zone by zone and how...

“Color Rules” Phase 4: Color Control Featuring DJ Cabler of WestRock and Clyde Tillman of Lithec USA

Phase 4 of the “Color Rules” is Color Control. Drive your press to target density! Watch this video for more insights on how to get there as quickly as possible and maintain density throughout the run. In the video, you'll learn about: The significance of a...

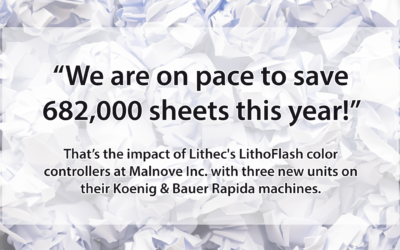

Packaging Printer to Add 3 In-pressColor Controllers in U.S. Southeast Facility

From Utah to Nebraska and now Florida, LithoFlash closed-loop systems are helping Malnove to save tons of money on paper costs. WOODSTOCK, GA — October 14, 2024 — Lithec, a global leader of inline color control and inspection systems for the graphic communications...

“Color Rules” Phase 4: Color Control Featuring Clyde Tillman of Lithec and Jack Frank of WestRock

Lets dive deeper into the importance of inline color control in modern printing. Watch as our experts Clyde Tillman and Jack Frank discuss how crucial this technology is for achieving precision and maintaining quality throughout the printing process. In the video,...

“Color Rules” Phase 3: Color Proofing Featuring Jim Raffel of ColorCasters and Jack Frank of WestRock

In this video, we discuss the importance of establishing proper profiles for proofing devices to ensure consistent and accurate print results. The conversation includes best practices for validating proofs against internal standards and maintaining predictable color...

“We find we can push more work through at higher speeds, with less waste, and keeping color consistency throughout the press run.”

ANDREW GOETT – President

“The LithoFlash system allows us to maintain the G7 standards in our offset print operations,” “WE DON’T HAVE TO WORRY ABOUT MATCHING, WE KNOW WE WILL CONSISTENTLY HIT OUR COLOR TARGETS.”

JOHN YERGER – Pressman

“We identified the Lithec Litho-Flash as a way to take our current capital equipment, apply a relatively inexpensive product, and level the playing field with our competitors”

JEFF KU – Superior Litho

“Quality is absolutely critical in packaging,” says Bernie Lacy, President of Litho Press. “We decided to install the LithoFlash to not only help cut down on our makeready times, but also to ensure we have even greater color consistency throughout the entire run.

With this installed, we can now print more jobs per day, and they are higher quality, with better color across the board.”

BERNIE LACY – Vice President

“Since we have installed Litho-Flash our biggest cost savings has come with the amount of sheets we have saved. We’ve pretty much cut our make-readies in half”

We wanted to bring our older presses up to the newest technology. Litho-Flash allows us to take an older press and achieve some of those quality expectations they have on new presses.

JIM EAKIN – Superior Litho