Developed by renowned industry experts, these guidelines have been established to ensure successful color management and ultimate printing efficiency.

By following this proven and productive roadmap, you’ll optimize efficiency and maximize savings—from pre-press all the way through to the final printed sheet.

With the right tools and processes in place, you can confidently manage color—instead of letting color manage you.

Each phase of the process requires a documented procedure that must be followed closely to achieve true success. When implemented correctly:

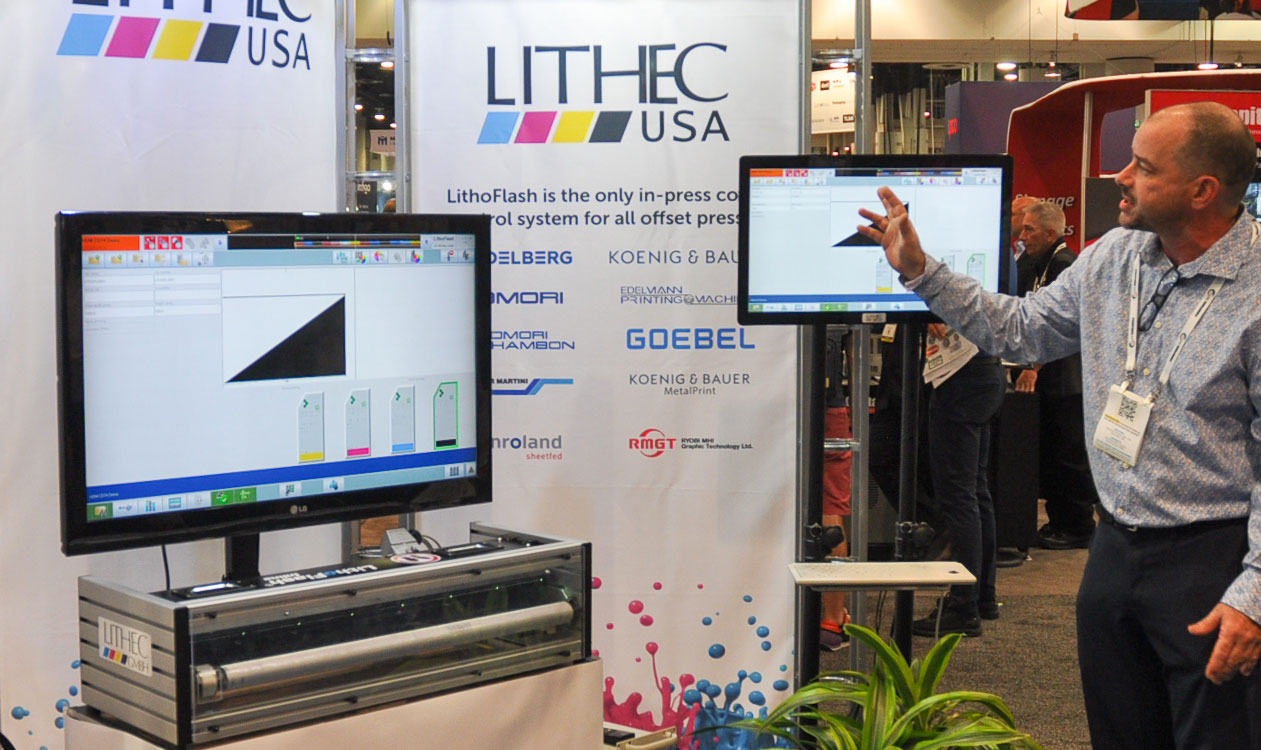

By installing LithoFlash and following the outlined Color Rules process, you will reduce waste, improve performance, and save time and money.

Packaging Printers are seeing makereadies in UNDER 200 SHEETS

Commercial Printers are seeing makereadies in UNDER 100 SHEETS

Fill out the form below to schedule a LIVE DEMONSTRATION of the LithoFlash Inline!

Our Four Phase Color Rules Process will Streamline your Pressroom!

- The process is simplified

- Color consistency is ensured

- The press operator playing field is leveled

- Training new operators becomes easier

- Press problems are minimized

- Huge savings are realized

Is your press mechanically and chemically stable enough to be consistently replicated every day? Color management alone can’t control an unstable printing press. A process must be in place to manage and verify press condition, along with the following mechanics:

Color management alone can’t control an unstable printing press. A process must be in place to manage and verify press conditions. We sit down with DJ Cabler of Westrock, to talk about how they use data to streamline their color management.